Looking for a Wind Power Flange ? Discover our groundbreaking connector type for large diameter wind towers

SubseaDesign’s innovative connector design will enable the industry to achieve greater turbine capacity.

MAIN benefits

- Very high structural capacity with close to unlimited scaling capability

- Superior fatigue capabilities

- Time efficient and safe installation:

- Fewer bolts, 72 off M72

- No rotational alignment of TP/Tower

- No heavy lifting, all components are pre-installed before loadout.

- Tension in the bolt remains constant, with bending moment transferred trough the connector segments not the bolt:

- Improved fatigue life

- Aiming for inspection and maintenance free connector

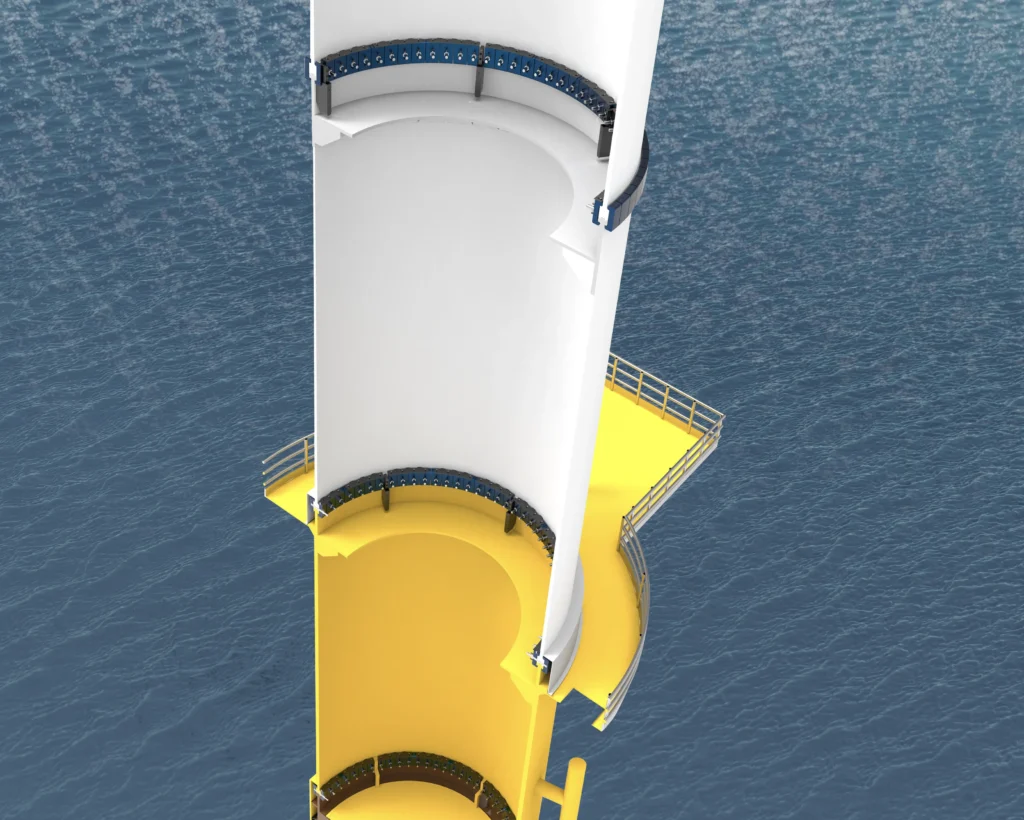

L-Flange installation

Motivations for finding new solutions :

- Enabling connection for offshore wind turbines beyond the limitations set by current solutions, for more extreme environmental conditions and more powerful (≥ 15 MW) wind turbines.

- The structural strength and fatigue limitations of existing connectors and flanges

- The maintenance and inspection requirements for L- and T- flanges

- The demand for more efficient installation

- The necessity for enhanced HSE compliance during the installation and operation of wind towers.

how our connector works

Play Video