REDUCE CYCLIC BENDING MOMENTS AND PROTECT YOUR WELLHEAD FROM EXCESSIVE LOADING

SubseaDesign’s innovative BOP tethering system reduces the cyclic bending moments that occur in the subsea wellhead during offshore drilling operations, reducing the risk of severe fatigue failure of critical components in the subsea well system. This is accomplished without compromising operational flexibility.

Cost-effective and innovative

SubseaDesign’s BOP Tethering System is a cost-effective and innovative solution that provides flexibility in adjusting the length of rope required for each tension line. This eliminates the need to have several lengths and reduces rigging time.

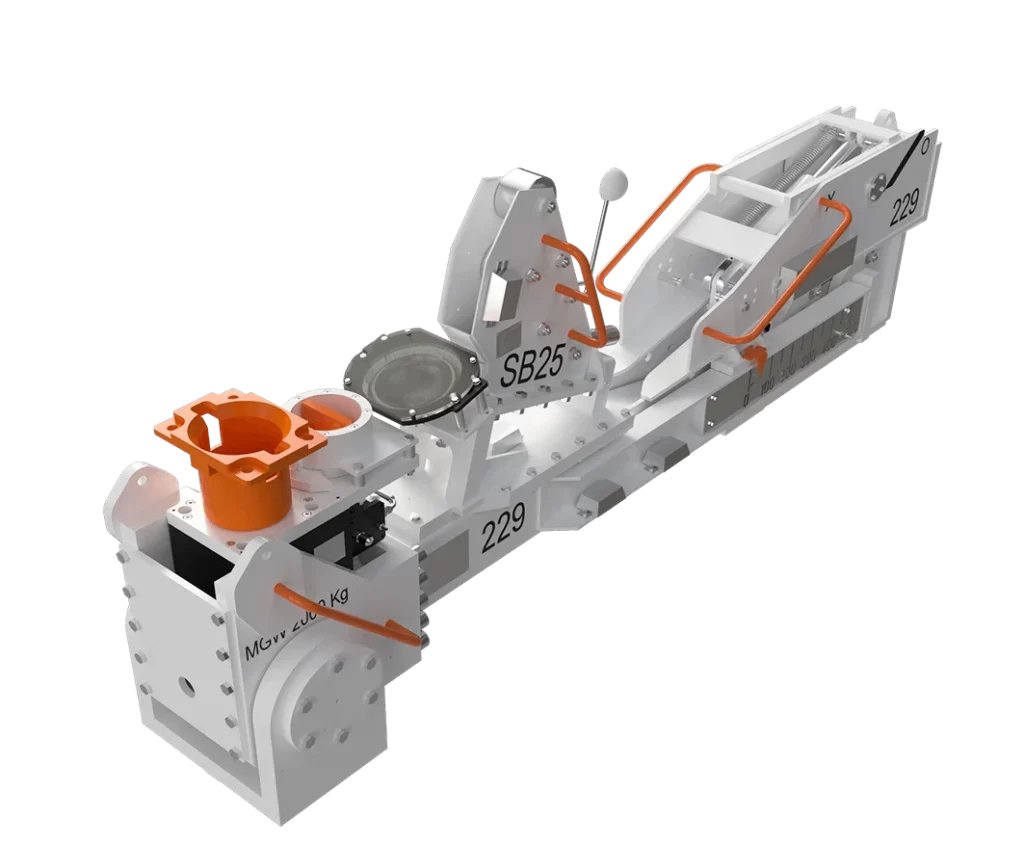

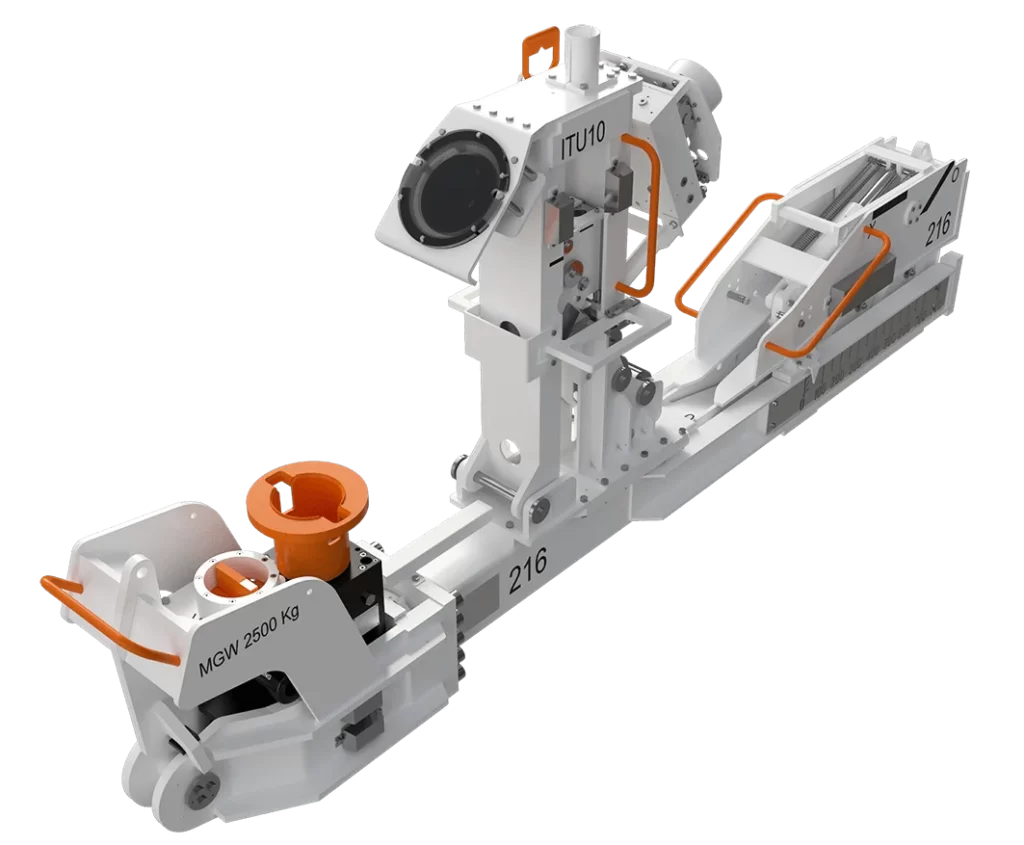

The heart of the system is the Linear Rope Tensioner (LRT), which can pull excess length of rope before being applied to final tension. The LRT can be equipped with two different configurations for initial tensioning. Either by lift line from surface (snatch block) or by a hydraulic operated tensioning unit mounted on the LRT. The latter is fully ROV operated and ideal for use in shallow water or on locations where it cannot be reached from the rig.

The LRT is equipped with a tension monitoring gauge. This allows the ROV to monitor and adjust tension as required. The LRT enables easy interfacing on all types of anchor points, both on templates and seabed. It also features a rotational range of 360 degree. Since the rope goes out of the LRT in upward direction, it will not be any clash with surrounding structures.

Adaptable to different BOP designs

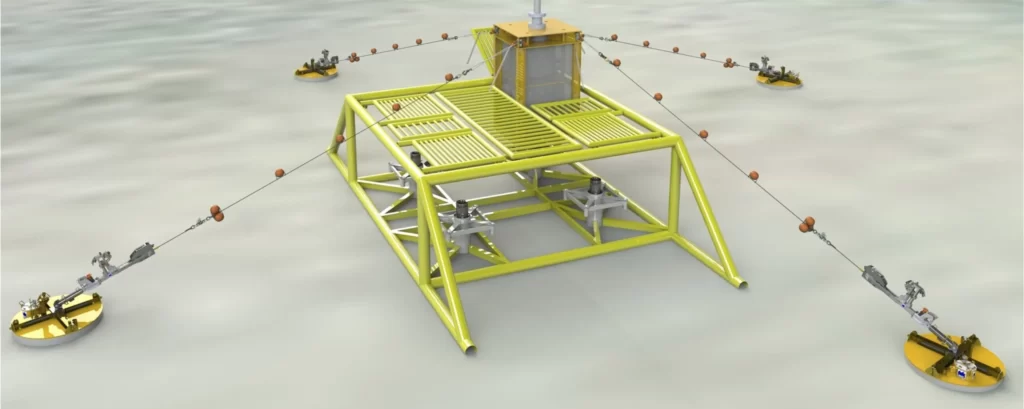

A complete BOP tethering system consists of several LRT’s which are individually tethered to the BOP. The number of tethers and anchoring coordinates are decided based on analyses of the system to achieve the optimal BOP tethering efficiency. Other optimization factors are loads on the existing infrastructure, well properties and soil conditions. The system is adaptable to different BOP designs.

The WLR system consists of several LRT’s which are individually tethered to the BOP. The amount and anchoring coordinates of the LRT’s are decided based on analyses of the system to achieve the optimal WLR efficiency. Other optimization factors are loads on the existing infrastructure, well properties and soil conditions. The system is adaptable to different BOP designs.

Specifications:

- Pull-in capacity: 4 T

- Pre-tension capacity @ 2700Nm torque: min. 30 T

- Design Load, ULS: 700kN

- ALS Load: 1050kN

SubseaDesign provides a wide range of services to support the delivery of subsea production systems. These include:

- SubseaDesign delivers BOP tethering system drawings and efficiency analyses to ensure that the client's requirements are met.

- Geotechnical analyses are conducted to ensure that the installation site is suitable for tethering.

- SubseaDesign conducts anchoring point (Tension supports, clump weights, suction anchors etc.) design and installation as well as tensioning mechanism (LRTs) design and installation. These components are used to secure the subsea system and ensure its long-term viability.

- SubseaDesign supports clients through detailed installation procedures and operational support for their production systems. This includes providing repair, maintenance, testing and storage of equipment (WLR test jig with load test up to 105 T).