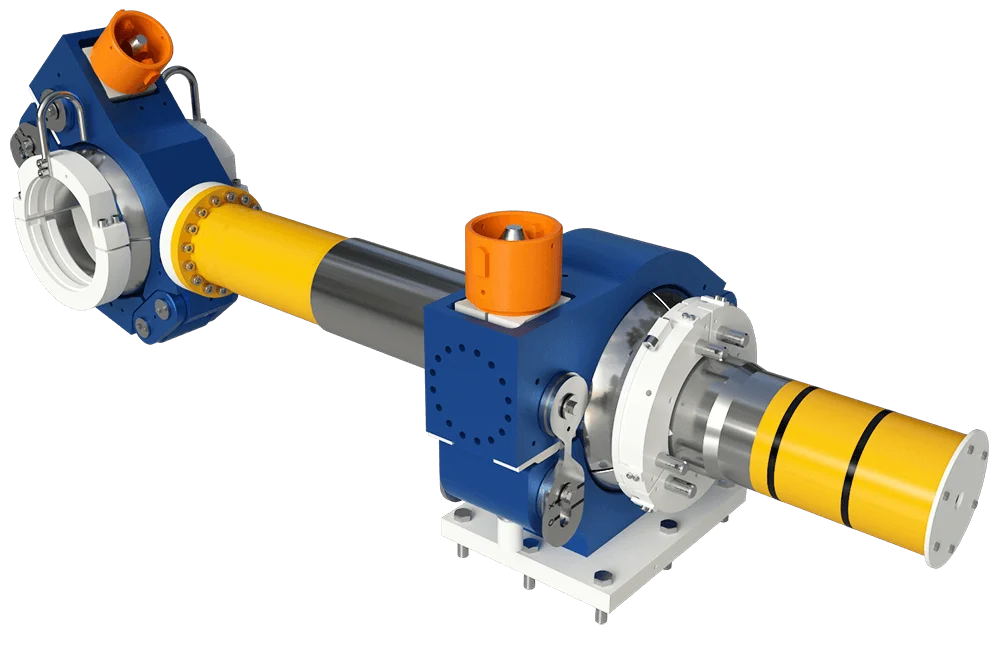

THE FLEXIBILITY REQUIRED DURING TIE-IN AND THE SUPPORT REQUIRED DURING OPERATION.

The SubseaDesign Anti-Vibration-Clamp prevents flow induced vibration to escalate above threshold where piping arrangement could see fatigue damages.

Pure mechanical design with no active hydraulic components

how it works

The locations and quantity of the Anti-Vibration Clamps are determined by the flow/piping analyses and the given layout of the module/structure. Required movement of the piping during any connection/disconnection will determine the overall dimensions.

Before tie-in, the Anti-Vibration-Clamp is free to move in all directions and angle at low friction. When the piping is connected, the Anti-Vibration-Clamp are closed and the piping system will have acceptable characteristics to prevent flow induced vibrations.

Assembling into manifold module

features and benefits

- Prevents flow induced vibration to escalate above threshold where piping arrangement could see fatigue damages

- Pure mechanical design, none active hydraulic components

- Grab around the piping in one end and secure the stationary part in the other end

- Allow for flexibility during assembly and connection of piping system

- Can be installed on existing piping system subsea

- Clamps are operated by ROV

- 4 off Anti-Vibration Units in service on subsea templates

product verification

- Verification testing in workshop to simulate horizontal connection between XT and manifold

- Good correlations between analyses and test results

Workshop testing to confirm functionality

Technical Data

| Design code | ISO 13628 |

| Size, outer diameter of pipe | Up to 12 inch |

| Working length | Adjusted for application |

| Material | Typical Carbon steel, interface item to pipe will be the same as pipe |

| Coating | Typical Norsok system 7, or as required |