TAKE FULL CONTROL OF THE PIGGING OPERATION

The SubseaDesign pig stopper keeps control of your pig launching sequence. It maintains the pig position before launch.

It is quick and easy to operate for the ROV.

Subsea pig stopper features and benefits:

- The subsea pig stopper prevents the pig to move unintended and prevents more than one pig to be launched simultaneously

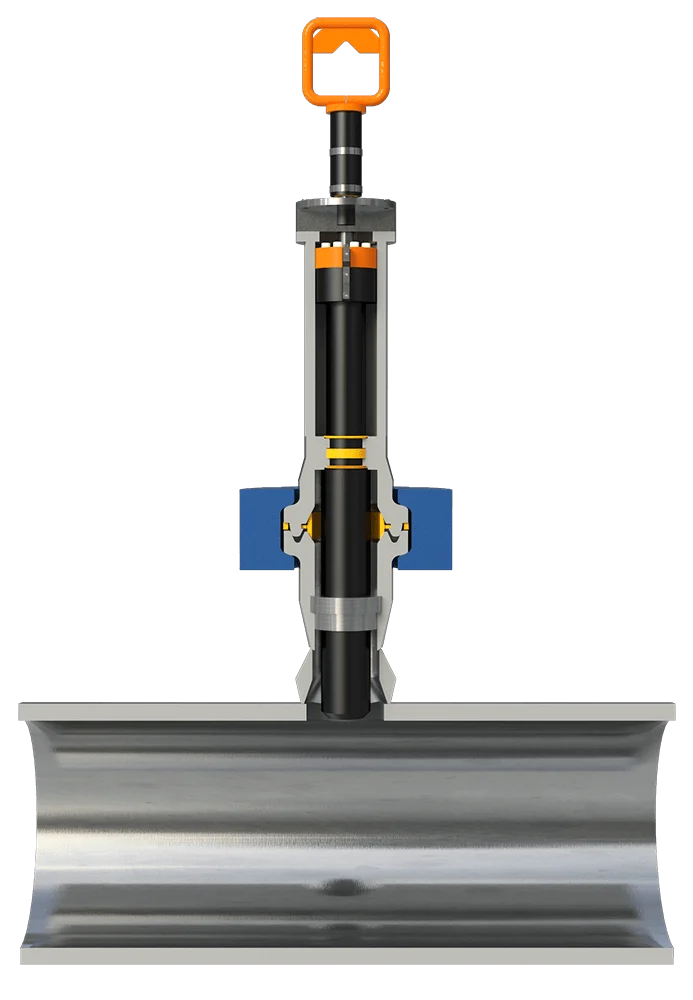

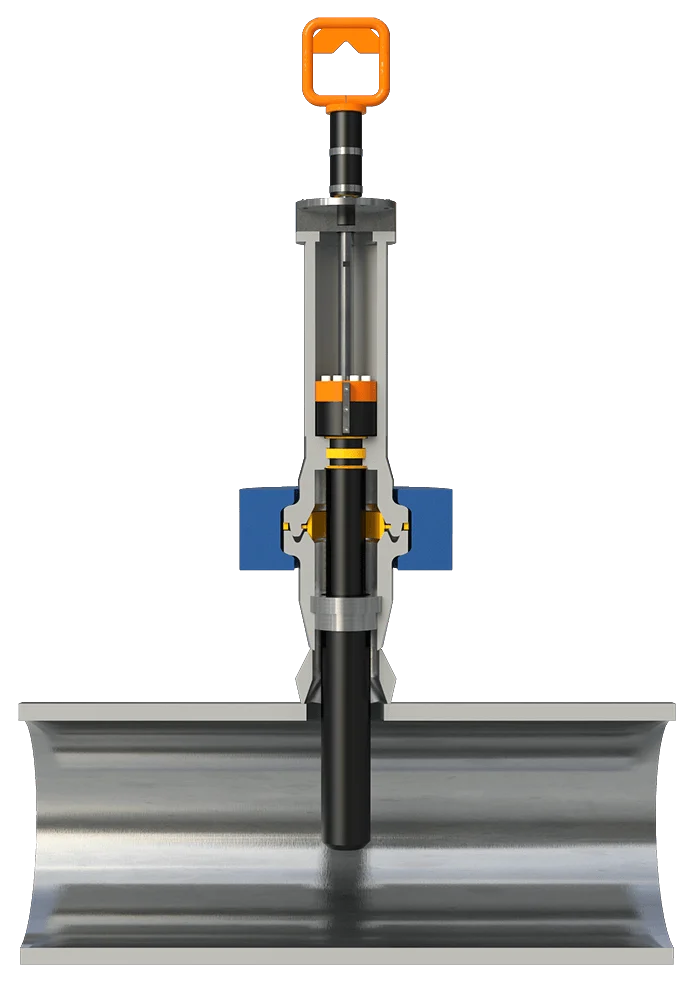

- The pig stopper is operated by the WROV manipulator by rotating the flexible handle until the stopper is in end positions.

- ROV operator is based on non-rising stem principle.

- Metal seals at end positions with polymer back-up seal

- Stopper rod extends to center of pipe

- Horizontal, vertical or in-between position to give access to operator

how it works

The handle is rotated by the WROV manipulator, the nut fixed to the stopper bolt transfer it to its end positions. The flexible handle is equipped with links to prevent bending of the drive screw.

The indicator shows the correct positions for the stopper bolt. In the end positions the pig stopper has metal seals to give a leak tight permanent connection for the internal pressure.

D-handle with flexible links

End flange with thrust bearings

Position indicator

SeAlign clamp and hub connection

Weld-o-let welded to pipe

Testing and Qualifications

| Design code | ISO 13628 |

| Size | 4” ID |

| Design pressure | 515 bar |

| Max. water depth | No limitation |

| Design temperature | -29°C to 121°C |

| Coating | As required by project |

Technical data

| Stopper bolt | Super Duplex 25%Cr |

| Housing | Super Duplex 25%Cr |

| Flanges | Super Duplex 25%Cr |

| Clamp | Super Duplex 25%Cr |

| Drive screw | Super Duplex 25%Cr |

| Receptacle | Super Duplex 25%Cr |

| Nut and bearings | Al bronze |

| Seal | Inconel x-750 |

| Weight | 26 kg |

| End to end dimension | 1050 mm |

| Flanges | API, ASME or SPO, Grayloc, SD flange or to Client specification |