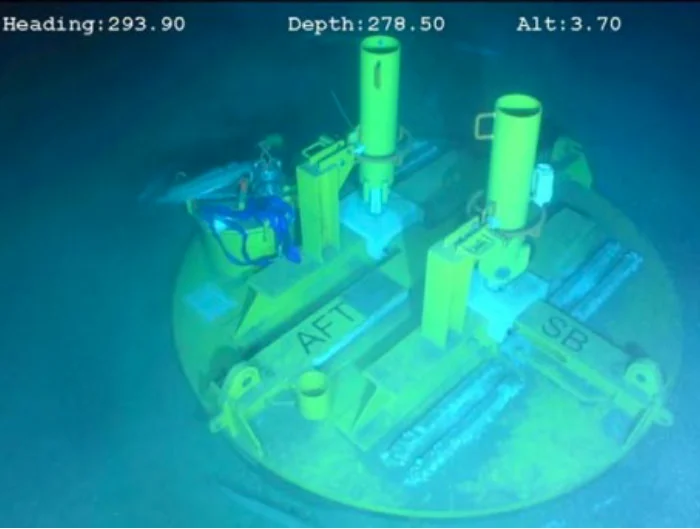

Suction anchor solutions

SubseaDesign provides full service within suction anchor design, fabrication and testing.

- Geotechnical calculations

- Structural calculations / analysis

- Cathodic protection design

- Lifting analysis and certifications

- Transportation and installation analysis.

- Fabrication and testing.

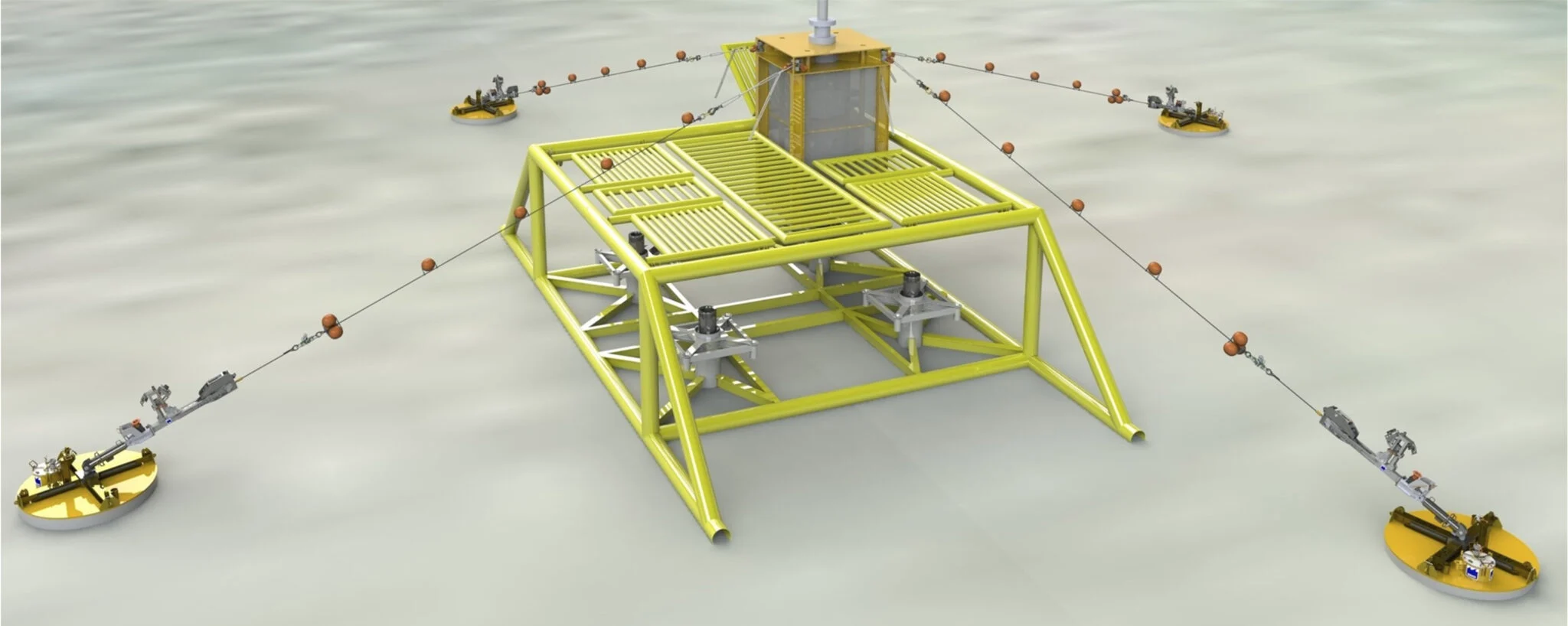

Mooring line support features and benefits

- Optimized for the given soil condition

- Integrated suction hatch

- Cost effective fabrication sequence

- Short delivery time

interfaces

- Suction stab receptacle can be either on the hatch cover or anchor top plate

- Suction hatch with integrated stab receptacle

- Different soil condition suitable for suction anchor

- Installation and handling lifting point as required for transport and installation

- Interface with various mooring line connection

- Delivered with anodes

- Delivered with electrical strapping

how it works

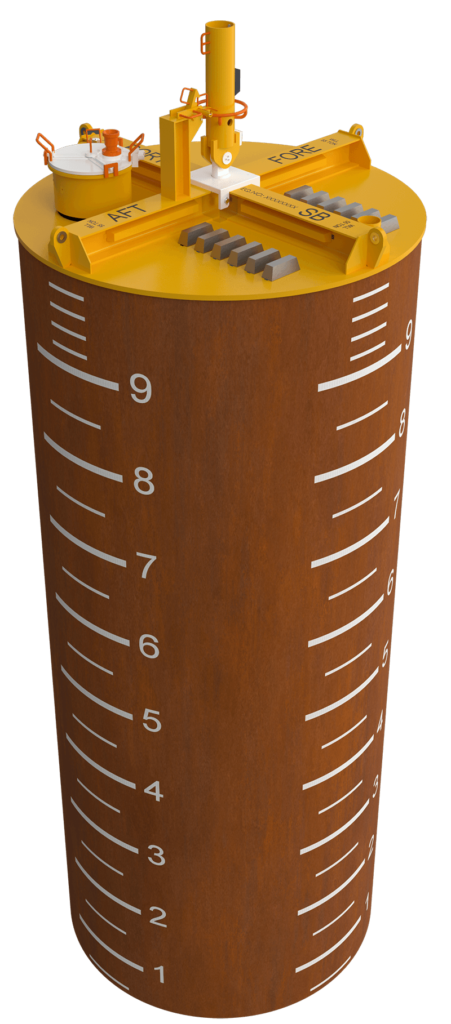

After the suction anchor has landed on seabed at location and self penetration stopped, the suction hatch is closed and suction is applied until the anchor reaches target depth.

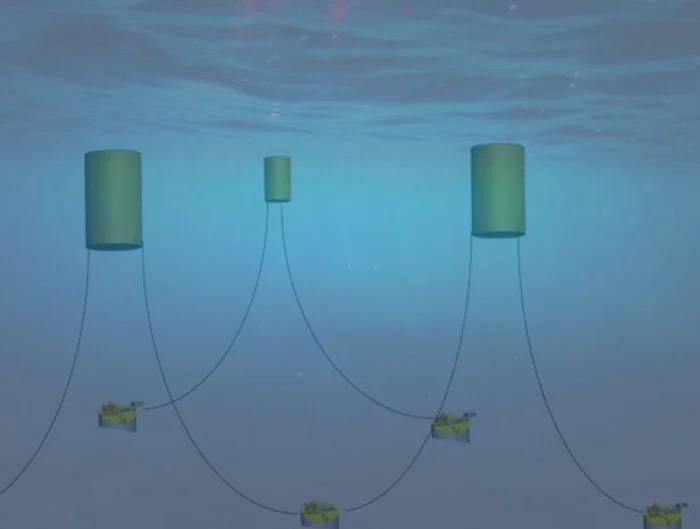

application

Mooring lines support for BOP during drilling

Mooring lines support for offshore windmills

Seabed securement via suction anchors.

technical data

| Design code | ISO 13628 DNVGL-ST-E237 DNVGL-RP-C212 DNVGL-RP-E303 ISO 19901-4 |

| Diameter | Largest delivered is 6 m |

| Length | Longest delivered is 12 m |

| Design suction pressure | Up to 20 bar |

| Design over pressure | Up to 20 bar |

| Max. water depth | No limitation |

| Lifetime | 25 years |

| Coating on top section | Typical Norsok system 7, or as required |