MISALIGNMENT FLANGE ELIMINATING THE TIE-IN BENDING MOMENT

SeAlign combines misalignment capability with robustness and a sealing system that is unaffected by external loads.

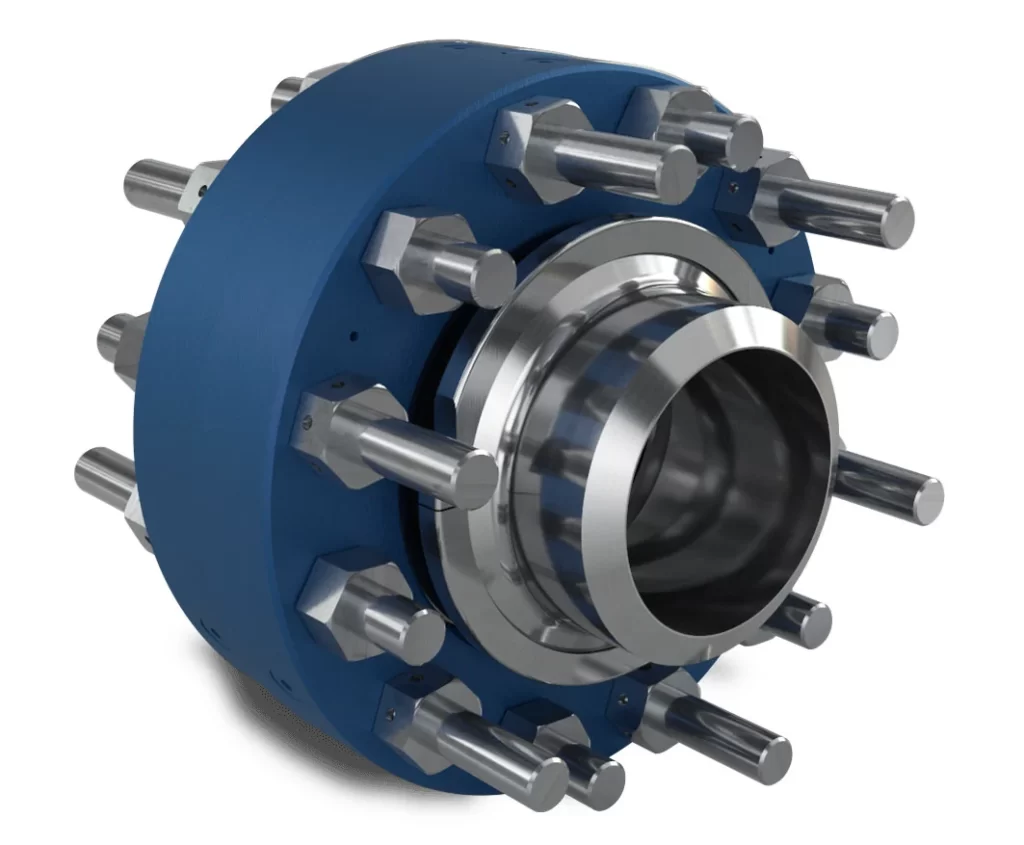

The SeAlign flange is supplied as diver flanges with swivelling clamp rings and stud bolts.

SeAlign ROV operated connectors with 3-segmented, single drive screw clamps and complete vertical or horizontal tie-in systems is also available.

With the SeAlign misalignment flanges the tie-in bending moment is eliminated. Significant savings can be materialised from reduced vessel time, shorter spools and ease of installation.

UP TO 3° DEGREES PERMANENT MISALIGNMENT

The SeAlign connection system is designed to provide a leak-tight connection while accommodating a given hub misalignment (+/- 3 degrees up to 20”, +/- 2 degrees for larger sizes) in all directions before make-up. This reduces bending moment loads to a minimum and simplifies tie-in.

The connector has been designed with ISO 13628-7 as the primary design code for strength and leakage criteria, with additional methodology from API 6A and API 17D. The connector is classified as API 6A Other End Connector (OEC), with fabrication and quality requirements per PSL 3. The connector meets requirements of DNV-ST-F101.

TECHNICAL DATA

| Connector size | 6″ | 8″ | 10″ | 12″ | 14″ | 16″ | 18″ | 20″ | 32″ | 36″ |

|---|---|---|---|---|---|---|---|---|---|---|

| Design/fabrication codes | ISO 13628-7, API 6A, API 17D, DNV-ST-F101 | |||||||||

| Materials selection | Hubs: ASTM A694 F65/F60 w/ NA 625 cladding | Seal – Titanium Gr 5 | Clamp ring: AISI 4140 / ASTM A182 F22 Stud bolts: ASTM A320 L7 | Nuts: ASTM A193 7L |

|||||||||

| Typical design life | 20-50 years | |||||||||

| Design temperature range | –30/+121 °C | |||||||||

| Design pressure | 690 bar | 690 bar | 517 bar | 517 bar | 345 bar | 400 bar | 345 bar | 250 bar | 250 bar | 250 bar |

| Maximum test pressure | 1035 bar | 1035 bar | 775 bar | 775 bar | 517 bar | 600 bar | 517 bar | 375 bar | 375 bar | 375 bar |

| Depth rating | 1500 m | 1500 m | 1000 m | 1000 m | 500 m | 500 m | 500 m | 500 m | 500 m | 500 m |

| Maximum hub misalignment | +/- 3 ° | +/- 2 ° | ||||||||

| Tie-in bending moment | 0 kNm | |||||||||

| Hub diameter | 250 mm | 325 mm | 410 mm | 480 mm | 540 mm | 615 mm | 690 mm | 750 mm | 1200 mm | 1325 mm |

| Hub diameter | 135 mm | 190 mm | 245 mm | 285 mm | 320 mm | 375 mm | 427 mm | 470 mm | 795 mm | 885 mm |

| Outer dimensions (OD and WN-WN length) | Ø440x 425 mm | Ø540x 465 mm | Ø635x 500 mm | Ø700x 530 mm | Ø760x 605 mm | Ø870x 585 mm | Ø965x 640 mm | Ø1050x 735 mm | Ø1630x 1000 mm | Ø1800x 1040 mm |

| Typical flange pair weight (hubs, clamp rings, studs, and nuts) | 230 kg | 325 kg | 475 kg | 605 mm | 855 kg | 1120 kg | 1515 kg | 2080 kg | 6315 kg | 8545 kg |

| Stud bolts | 8x M36 | 12x M42 | 12x M42 | 12x M48 | 12x M48 | 16x M48 | 16x M56 | 16x M56 | 24x M64 | 24x M72 |

| Nominal stud bolt tension | 415 kN | 570 kN | 570 kN | 750 kN | 750 kN | 750 kN | 1030 kN | 1030 kN | 1360 kN | 1760 kN |

| Stud bolt tension tolerance | +/- 20% | |||||||||

The current size range covers 6″ to 36″, with custom sizes available on request.

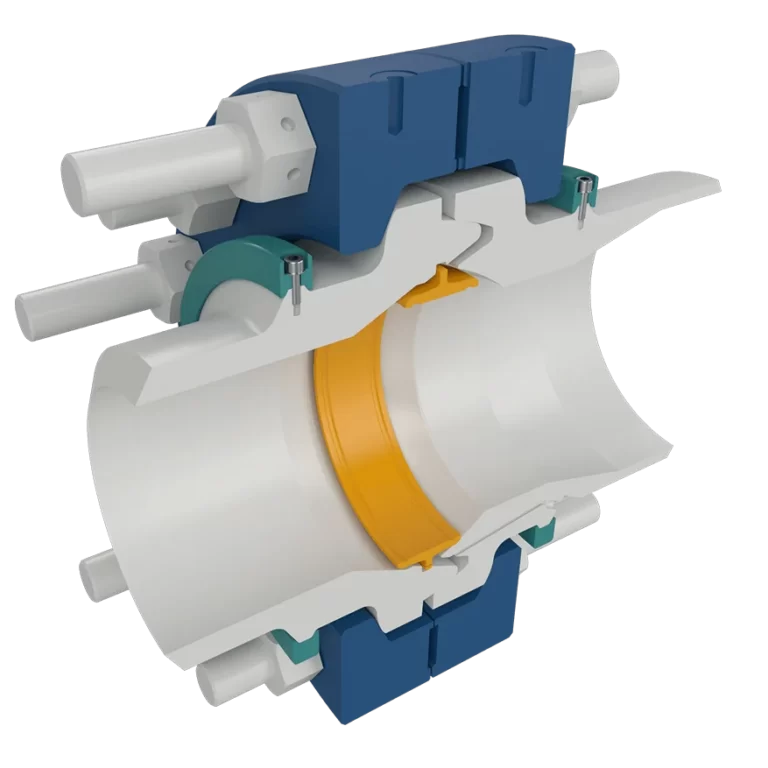

The main features include:

- Up to +/- 3˚ hub misalignment

- Acts as ball joint – locked at make-up

- Eliminates tie-in bending moment, only axial load required

- Mechanical end stop in hub profile

- Leak tight at all misalignment angles, M2M

- Design pressure and depth rating to suit most applications

The benefits of SeAlign may be realized by one or more of the below:

- Reduced spool size

- Relaxed fabrication tolerances

- Reduced operational loads

Divers making up an 18” SeAlign

Components

Female Hub

Clamp retainer ring

Male Hub

Clamp Ring

Metal Seal

Metal Seal

Stud Bolt

Nut